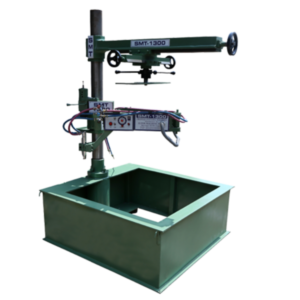

Centrifugal Self Priming Mud Pumps

Gearbox Block

Power Source Electric

Motor Phase Three Phase

Application Industrial

Capacity Upto 250 m3/hr

TDH Up to 34 MLC

Delivery Size Up to 150 mm

Backed by our experienced team of professionals, we have been able to put forth a quality assured array of Centrifugal Self Priming Mud Pumps. Having back pull-out design, these pumps are ideal for the purpose of engine drive pumping. Moreover, known for their sturdy construction and error free functioning, these pumps are in great demand among industries.

Features:

Long life due to replaceable wearing parts

No foot valve required

Automatic air release during priming

Grease lubricated deep grooved ball bearings

Quick automatic self priming action

Dynamically balanced rotating parts

Repair possible without disturbing the pipe connection

Non-clogging impeller to handle suspended solids

Portable when fitted on trolley/trailer

Suitable for motor/engine

Non-clogging and handles solids up to 50 mm.

No priming of suction pipe line

Application:

De watering, mud, marine, effluent, hotel, swimming pools

Vessels, industrial-pumping petroleum products and chemical

Civil construction de watering foundations, trenches and pits, filter press feeding, ETP, STP, waste water treatment plant

Mobile machinery – cooling water for marine engines and shovels

Public utilities like sewage pumping

Pier, excavations, pot-holes, gram panchayats, municipalities, public health departments and large housing colonies

Industries like chemical, pharmaceuticals, food, cement, paper, sugar, salt, steel and other for liquid cargo from freighter and barges.

Details:

Volute Casing: heavy duty built in volute having self priming features and integrally cast with base from closed grained C.I. castings

Impeller: Non-clogging designed for high efficiency and semi open type and are finished for perfect smooth flow

Shaft: made of EN 8 / SS 410 steel specifications ample size to transmit power without distortion or vibration

Bearing: anti friction ball bearings, single row deep grooved heavy selected to provide maximum service and grease lubrication arranged by grease cups

Stuffing Box: deep gland box used with graphite packing are lubricated by lantern ring with grease

Flanges: companion flanges are supplied along with pumps

Rotation: marked with arrow on casing of each pump, it should be checked before coupling with prime mover

Base Plate: suitable base frame can be supplied with pump.

Industries Covered :

Pharmaceuticals & Chemical : Oil Extraction Plants

Pulp & Paper Industries : Waste Oil Refining Plants

Dyes & Intermediates : Solvent Transfer

Marine : Pumping water from docks, ports, vessels

Industrial : Petroleum Products, chemicals, effluents, sewage, ash-water.

Civil construction : Dewatering foundation, trenches and pits

Mobile Machinery : Cooling water for marine engines and shovels

Public Utilities : Sewage pumping.

Material of Construction : Pumps are manufactured in variety of materials such as :

Cast Iron

Stainless Steel as per ASTM A 351/743 Gr. CF8, CF8M.

Carbon Steel / WCB.

Bronze

For More Details View PDF

Additional Information:

Item Code: FPE-S-FPE-SJ-Series

SMS Pump Engineers

General Inquiries

There are no inquiries yet.

Reviews

There are no reviews yet.